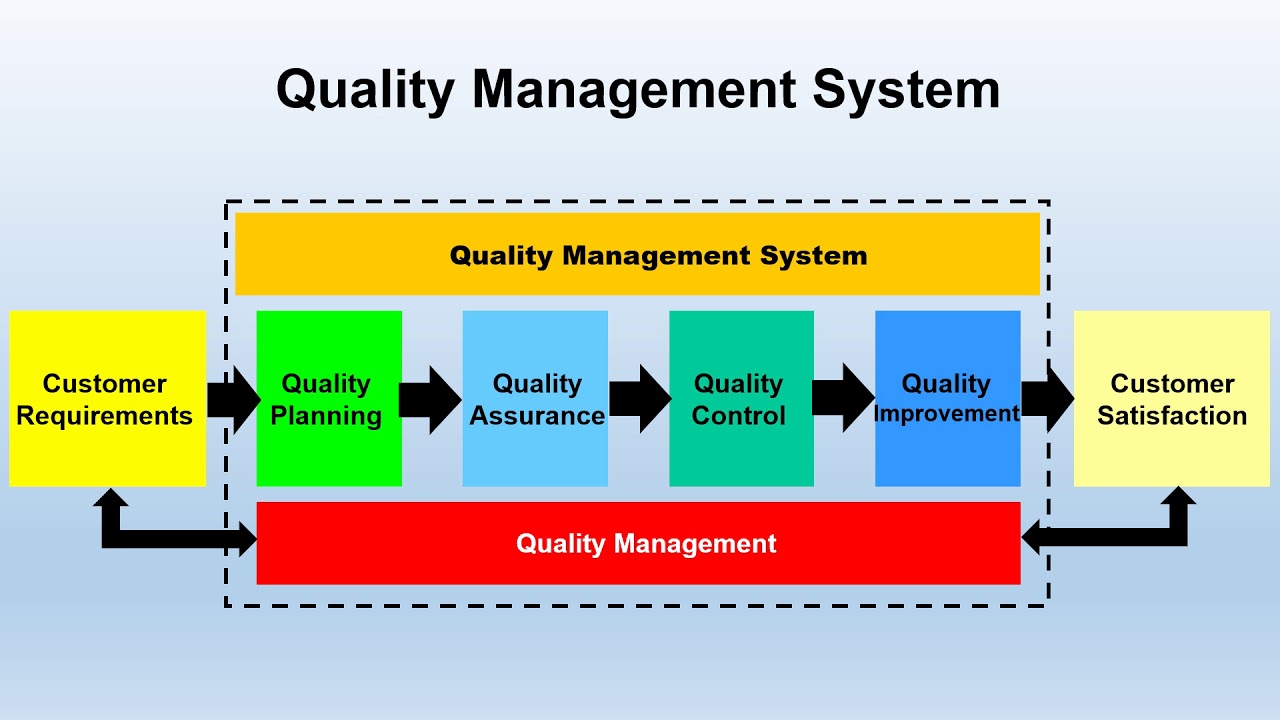

Here we will learn What is a Quality Management System? Top 5 Tips To Improve Quality Management in Your Shop by Garment Manufacturing Software. Quality Management is keeping a close eye on all processes and tasks that need to be done to keep your shop’s quality at the right depth. Quality assurance, planning, and execution, as well as quality control and improvement, are all included in quality management.

The Importance of Quality Management

Your company’s long-term success depends on attracting and keeping loyal customers. Product quality is the primary criteria by which your clients will assess you, along with on-time delivery. You must consistently provide your customers with high-quality products if you want to keep their business.

All custom manufacturers must use effective quality management procedures to guarantee a high standard of quality. Companies with the highest chances of gaining the trust and happiness of their clients are those that consistently produce high-quality products. The implementation of effective quality management methods will also boost your organization’s effectiveness and reduce costs by reducing waste. High levels of quality lead to repeat business, increased profits, and industry recognition.

Here 5 Tips To Improve Quality Management in Your Shop

1. Maintain a clean shop.

Maintaining a clean shop is one of the easiest methods to raise quality in your business. A clean workspace not only increases worker safety but also maintains your workplace running smoothly and efficiently, reducing errors and mistakes and raising quality. You must make precise standards for the hygiene of the shop floor and set aside time to clean up your store. Use the “Pick Up As You Go” strategy to train your staff to clean up after themselves so they can keep a clean shop floor. To keep your shop in good condition, make sure you regularly clear up unexpected mistakes.

2. Specify your quality standards

You must develop your quality standards before your store can supply high-quality products. Answer the following issue in order to do that: How will you define quality in your plant? Your answer to this query will serve as the basis for developing and executing quality management systems in your shop. You must think about how many faults you are ready to accept, the processes you want to improve, and the quality goals you want to achieve. Before putting into practice efficient quality management procedures, it is crucial to establish clear standards and goals. Take some time to select when you will check the following; some companies choose to do so after the product has been purchased.

Related Article- Cloud ERP Software for Garment Manufacturing Industries: VRS UNIERP

3. Have a quality control system.

The most important element in producing high-quality goods. Simply said, modern manufacturing is too complicated to operate without one. A business employs a quality management system, which is a collection of processes, procedures, and policies, to create items of a high standard that consistently satisfy customers and meet their needs. The easiest way for manufacturers to maintain quality in their shops, like with many other elements of custom manufacturing is to use their ERP system. Here Use Garment Manufacturing ERP Software systems have tools for quality control built in to enable custom manufacturers consistently produce high-quality products. These are designed to specifically address the demands of custom manufacturers. With an integrated system, an ERP enables you to set up, control, and analyze quality control.

4. Integrate quality into the mindset of your business.

It will be difficult to motivate your staff to focus on quality if quality is not integrated in your company’s culture. Your entire staff, not just your quality management manager, must be committed to quality. Everyone in your company must require training on how to analyze processes for quality and keep a look out for problems. Furthermore, you want to provide your staff the flexibility to offer ways to improve the efficiency and standard of your shop. As is pretty much a given in the complicated world of custom manufacturing, quality control frequently suffers the most during times of change.

5. Make use of technology.

The most important piece of technology you can deploy in your shop to ensure that you constantly deliver high-quality products is a QMS system integrated with your ERP. However, other technologies can also be useful. Don’t fail to appreciate how technology can improve quality control and shop efficiency. Data collection is an essential part of quality management, and there are a number of solutions on the market that can help you improve quality based on your operations.

Related Blogs- What are the Benefits of ERP Software for a Garment Manufacturing Company?

Conclusion

Never ever let quality management be a concern. One of the most critical things your shop can do to improve customer satisfaction and ensure the long-term viability of your business is to deliver high-quality products. Even though setting up quality management procedures may take some time, they will ultimately save you time and money while also improving customer satisfaction and loyalty.